SINGLE PHASE POLE MOUNT TRANSFORMERS

Single-phase pole-mounted transformers are essential components in electrical distribution systems, commonly seen mounted on poles to convert high-voltage electricity to a lower, more usable voltage for homes and businesses. These transformers are designed to be reliable and efficient, meeting industry standards such as ANSI, IEEE, DOE, and UL requirements for safety and performance.

Manufacturers like L/C Magnetics Inc. produce high-quality pole-mounted transformers, adhering to strict standards to ensure compliance and safety. Customization options are available to meet specific power requirements, with capabilities to produce transformers up to 10,000 VA. Additionally, reconditioned transformers are offered as a cost-effective option without compromising on quality.

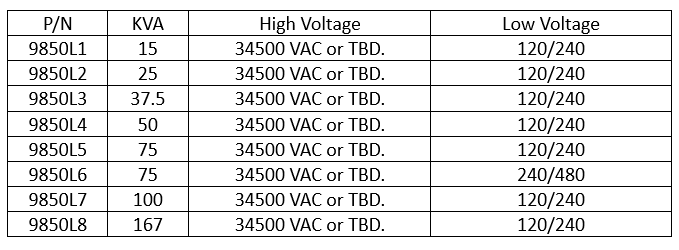

Specifications

Components of Single Phase Pole Mounted Transformer

- Core Material:

- Typically made from laminated silicon steel to minimize hysteresis and eddy current losses.

- Windings:

- Primary Winding:

- Connected to the high voltage side.

- Usually made from copper or aluminum.

- Secondary Winding:

- Connected to the low voltage side.

- Also typically made of copper or aluminum.

- Primary Winding:

- Insulation:

- High-quality insulation material such as enamel coating on wires.

- Oil-filled transformers use mineral oil for cooling and insulation.

- Core Construction:

- Laminated design helps reduce losses from eddy currents.

- Can be shell-type or core-type construction.

- Bushing:

- Insulated bushings provide safe passage for conducting the incoming and outgoing wires through the transformer casing.

- Cooling Mechanism:

- Natural air cooling (AN) or air-cooled (dry-type).

- Oil-immersed (ONAN – Oil Natural Air Natural) for better cooling and additional insulation.

- Tank:

- Houses the core and windings.

- Made from sturdy material to protect internal components.

- Radiators:

- For oil-filled transformers, radiators improve heat dissipation.

- Tap Changer:

- Allows for small adjustments to the output voltage by changing the transformer winding taps.

- Conservator:

- For oil-filled transformers, it accommodates oil expansion and contraction.

- Breather:

- Contains silica gel to absorb moisture from the air entering the conservator.

- Surge Protectors:

- Components like lightning arresters or surge arresters to protect the transformer from voltage spikes.

- Grounding:

- The metallic parts of the transformer are grounded to ensure safety and protection from electrical faults.

- Protective Devices:

- Includes fuses, circuit breakers, and protective relays.

Each of these components and considerations contribute to the efficient and safe operation of a single-phase pole-mounted transformer.

Technical Specifications

-

Rated Power Capacity:

- The amount of power the transformer can deliver, typically measured in kVA (kilovolt-amperes).

-

Voltage Ratings:

- Primary voltage (high voltage side) and secondary voltage (low voltage side).

-

Frequency:

- The operating frequency, usually 50 Hz or 60 Hz depending on the region.

-

Impedance:

- The transformer’s impedance affects voltage regulation and fault currents.

Installation Considerations

-

Pole Mounting Hardware:

- Brackets, bolts, and necessary fixtures to securely mount the transformer on the pole.

-

Location:

- Assess proper placement for optimal performance and minimal disruption; ensuring access for maintenance.

-

Clearance:

- Sufficient distance from other structures and vegetation to avoid hazards.

-

Grounding:

- Proper grounding to ensure safety and system integrity; ground rods, wire, and connections are crucial.

Optional Additions to Transformer

Optional Designs:

- Hermetically Sealed Construction:

- Sealed units to prevent oil exposure to air and moisture, reducing maintenance.

- Amorphous Core Transformers:

- Utilize amorphous metal for the core to significantly reduce core losses.

- Three-Phase Connection:

- Some configurations can be adapted for three-phase supply by interconnecting multiple single-phase transformers.

- High-Efficiency Designs:

- Transformers designed to meet higher efficiency standards, reducing operational losses.

- Low Noise Design:

- Special designs to minimize audible noise during operation, ideal for residential areas.

Optional Accessories:

- Load Tap Changer (LTC):

- For adjusting the transformer’s voltage output dynamically under load conditions.

- Buchholz Relay:

- A gas-activated relay for detecting internal faults in oil-immersed transformers.

- Pressure Relief Device:

- Relieves internal pressure build-up in oil-filled transformers to prevent tank rupture.

- Magnetic Oil Level Gauge:

- Indicator for monitoring the oil level inside the transformer’s tank.

- Oil Temperature Indicator:

- Monitors the temperature of the insulating oil to prevent overheating.

- Winding Temperature Indicator:

- Measures the winding temperature to ensure it remains within safe operating limits.

- Cooling Fans or Pumps:

- For enhanced cooling in high-load applications to maintain optimal transformer temperature.

- Explosion Vent:

- Provides a safe pathway for explosions to vent in the event of a catastrophic failure.

- Oil Filtration and Purification System:

- Keeps the insulating oil clean and free from moisture and contaminants.

- Radiator Valves:

- Allows for the isolation of radiators for maintenance purposes.

- Silica Gel Breather with Air Vent:

- Enhanced models of breathers to better manage moisture control.

- Surge Arresters:

- Additional protection against surges due to lightning or switching operations.

- Energy Monitoring Systems:

- For real-time monitoring of energy usage and transformer performance.

- Remote Monitoring Systems:

- Enables remote supervision and control of transformer performance.

- Anti-Theft Devices:

- Measures to prevent or detect unauthorized access or theft of transformer components.

These optional designs and accessories improve the operational capability, longevity, and safety of pole-mounted transformers, tailoring them to specific needs and environments.

Operational Aspects

-

Load Considerations:

- Understanding the load profile to avoid overloading and ensure efficient performance.

-

Efficiency:

- Assessing transformer efficiency to reduce operational costs and energy losses.

-

Cooling Requirements:

- Effective cooling mechanisms to maintain performance and extend life; air natural or oil cooling.

-

Maintenance Schedule:

- Regular maintenance to check for oil levels, insulation, connections, noise, and overall health of the transformer.

To discuss your specific application, please call our phone number at (714) 624-4740, or send us an email at quote@lcmagnetics.com.

CONTACT FOR A FREE QUOTE

Need a replacement for urgent and obsolete transformers and inductors?

Our engineers can respond within the hour.

EMAIL: quote@lcmagnetics.com

PHONE: (714) 624-4740

L/C MAGNETICS INC.

MANFACTURER, RESELLER, AND DISTRIBUTOR OF CUSTOM TRANSFORMERS AND INDUCTORS

DRY TYPE TO OIL FILLED PRODUCTS FROM 0.1 KVA TO 50 MVA

CELEBRATING 35 YEARS IN BUSINESS

CARL E. HOLMES COMPANY -- CEHCO

MANUFACTURER OF CUSTOM DC RECTIFIERS, TRANSFORMER RECTIFIER ASSEMBLIES, AND POWER SUPPLIES

DIVISION OF L/C MAGNETICS

RECTIFIER SPECIALIST SINCE 1945